API B Series

API B Series Pumping unit is a kind of light-weight beam-pumping unit. It adopts beam balance and is widely used as ground power equipment in rod pumping work. Our product accords with API Spec 11E Specifications for pumping units and Chinese Petroleum industry standard GB/T29021-2012 and other related standardsPerformance and advantage:

- Simple structure, convenient operation and maintenance, long service life.

- Involute or double arc herringbone gear reducer works smoothly and stably.

- Light-weighted, convenient to install and transport.

- Suitable for the oil-pumping work for lower stroke length, light load and shallow well

API C Series

API C series beam-pumping unit adopts crank balance. It is the most common and most widely used ground power equipment in rod pumping work. Our product accords with API Spec 11E Specifications for Pumping Units and Chinese petroleum industry standard GB/T29021-2012 and other related standardsPerformance and advantages

Modularization and virtual manufacturing technology have been adopted in the process of designing. Products structure has been optimized, and the parts are of high standardization, universalization and serialization. Finite-element analysis has been adopted to the key structure to realize stable performance and high reliability. The reducer adopts symmetrical involute gear transmission or double circular arc herringbone gear transmission, with good sealing, low noise, smooth running and reliable durability. The unit has the characteristics of simple operation, easy maintenance and long service life.

API M Series

API M Front-mounted pumping unit adopts crank-balance. The special structure reduces horsehead acceleration upstroke, thus reducing static torque peak, increasing load capacity and saving energy. It is widely used in oil fields throughout the world. Our product accords with API Spec 11E Specifications for Pumping Units and Chinese petroleum industry standards GB/T29021-2012 and other related standards.Performance and advantages

The gear reducer lies at the front of samson post. Impact structure, convenient operation and maintenance, longer service life. Good balance effect reduces maximum torque of gear reducer. Energy-saving, smooth and stable operation; The load carrying capacity is more reasonable; it is not easy for pitman arm or equalizer get fatigue damage; less mechanical wear and lower noise.

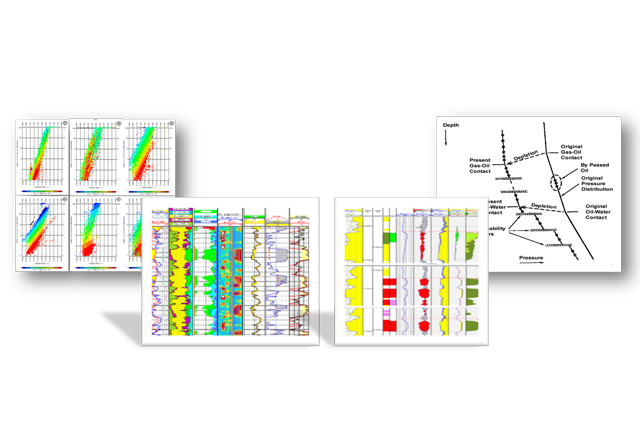

Production Technology / Optimization

- • Analysis of historical production data

- • Manage production decline

- • Manage gas / water exploration

- • Model and recommend production system design and operations for maximum value delivery

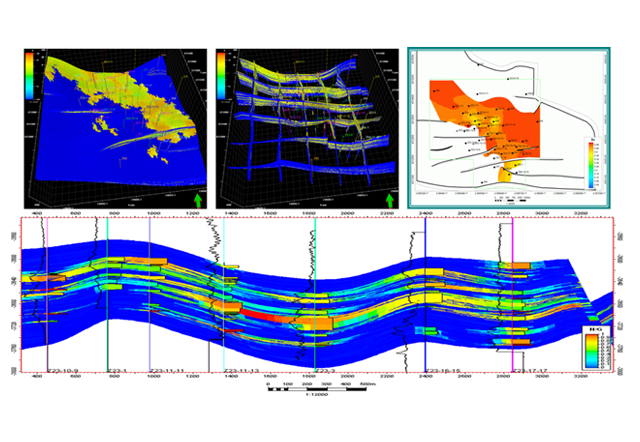

Engineering Resevoir

- • Single well / sector / field model simulations

- • Analysis of fluid characteristics / PVT laboratory results

- • Synthesis of specific basic analysis results

- • Good test description

- • Good nodal analysis

- • Hydrocarbon reserves and reserve assessment

- • Transient Analysis Rate (RTA)

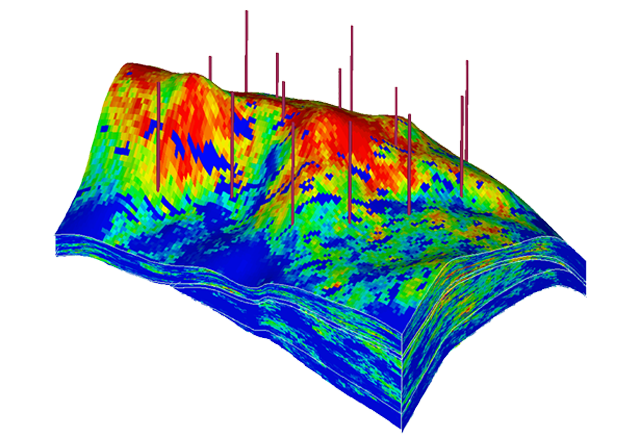

Geological Modeling

- • Data collection, validation and correlation

- • Structural and stratigraphic seismic interpretation

- • Structural model circle

- • Facial analysis and mapping

- • 3D integrated reservoir characteristics and modeling

- • Well placement and reservoir operation modeling

- • Integration with reservoir simulation

Petrophysical Analysis

- • Integrated formation assessment

- • Probable lithology and porosity modeling

- • Capillary pressure and J-function fluid saturation modeling

- • Synthesis of basic laboratory analysis

- • Service services (digitization, editing, conversion, normalization, archiving)

Database Services

- • Data collection, validation and QC

- • Geological, geophysical, petrophysical and engineering data

- • Integration of multiple data sources

- • History and existing usage databases

- • Experience with all basic data models and standards

Spatial Data Analysis inside the GIS setting

Our company is a full-spectrum oil service provider and consultant capable of conducting research in various subsurface areas within Geophysics, Petrophysics, Geology, Geo-modeling, Reservoir Engineering, Simulation. Our vision is to train a large number of disciplined technical teams to coordinate site development, reservoir management and implementation of projects that continue production analysis. Therefore, we have gathered a group of technical specialists with strong experience in the development of oil and gas fields, geographical sciences, engineering and operation.

API RM Series

API RM Reverse Mark Pumping Unit is similar in appearance to conventional pumping unit. It adopts phased crank, and is widely used as energy efficient pumping unit in rod pumping work. Our product accords with API Spec 11E Specifications for Pumping Units and Chinese petroleum industry standard GB/T29021-2012 and other related standards.Performance and advantages

Modularization and virtual manufacturing technology have been adopted in the process of designing. It is similar in appearance and motion characteristics as conventional pumping unit. The reducer adopts symmetrical involute gear transmission or double circular arc herringbone gear transmission, with good sealing, low noise, smooth running and reliable durability. Phase angle on crank reduces maximum torque peak of gear reducer; increase crank angle between two limit positions to improve dynamic performance, reduce motor power; obvious energy-saving effect. The structure is optimized; the parts are of high standardization, universalization, and serialization.

F Low Profile Pumping Unit GB/T29021-2012

F Low Profile Pumping Unit is a new type of non-beam pumping unit. It adopts flexible transmission and can be folded. This is a new type of ground power equipment in rod pumping work. Our product accords with Chinese petroleum industry standard GB/T29021-2012 and other related standards.Performance and advantages

Flexible transmission of rotary drum and belt reduces impact load and extends service life of gear reducer; Unique phased cranks and complete crank balance have a good saving effect. The gear reducer adopts symmetrical divided-flow double arc herringbone gear. It is featured with better seal, lower noise, steady and reliable running. Mass-to-volume ratio of overall unit is low. It can be folded to make it convenient to install and transport. It has simple structure, convenient operation and maintenance, and better cost performance.

Double horsehead pumping unit GB/T29021

Double horsehead pumping unit is a kind of energy-saving product with long stroke and low stroke frequency. It is suitable for the recovery of moderate and low viscosity oil and high water-cut crude oil. The product accords with Chinese petroleum industry standard GB/T29021-2012 and other related standards.Performance and advantages

It adopts reducing arc-shaped back walking beam and flexible connection between walking beam and equalizer. Advantages of conventional pumping unit are retained. Long stroke length, small dynamic load, little torque fluctuation, high efficiency, low energy consumption, smooth work and easy to start. The stroke length is increased by 70% around, energy consumption reduced by 20~30% and power reduced by 50%, compared with conventional pumping unit of the same model.

Adjustable Diameter and Changeable Torque Beam Pumping Unit GB/T29021-2012

Adjustable diameter and changeable torque beam pumping unit is technical innovation based on beam pumping unit. It changed traditional balance type and has good balance effect. The product accords with Chinese petroleum industry standard GB/T29021-2012 and other related standard.Performance and advantages

Walking beam achieves crank offset balance with the unique design. It is simple to adjust. The weight box is close to ground as horsehead reaches the top dead point, which is easy to add or subtract the small counterweight of weight box. It is in good balance, adjusting the balance precisely according to load peak value. Locking up walking beam and samson post while adjusting stroke. It changes the situation of low security, high labor intensity and being assisted by crane.

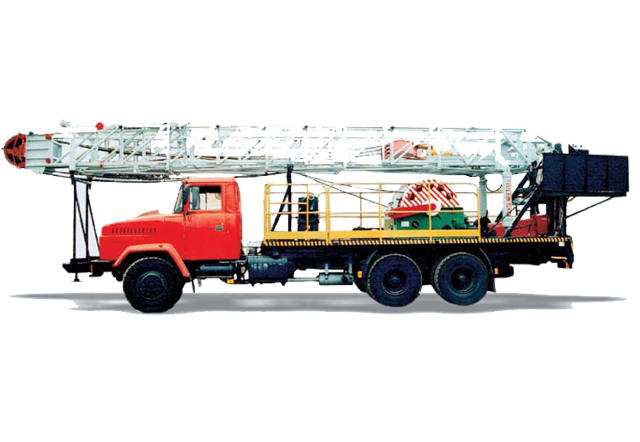

URB 41

We design, build, and support a wide range of self-propelled and trailer-mounted well servicing, workover, and mobile drilling rigs for the industry. Combining purpose-built components with the rigorous attention to quality and construction by our experienced engineering groups provides the customer with mobile drilling rig equipment that performs exceptionally well. The URB-41 exploratory drilling rigs are designed for mineral exploration, studying the mineral resource base and preparing technological maps for the extraction of reserves; as well as for geological work for the design, construction and reconstruction of enterprises.Technical features:

An axial arrangement of equipment that allows you to transport drilling tools by placing them on both sides of the machine, i.e. evenly distribute the mass of the load. Friction clutch in the transfer case, due to which the compressor or mud pump is switched on without loss of power flow to the hydraulic system. Special control panel for the convenience of the operator from the ground. Built-in electronic controller of drilling parameters, visually displaying the pressure of the mud pump, flushing fluid flow rate (in l / min.), Pressure in the hydraulic system, compressor pressure, etc.

URB 50

The UP 50 exploratory drilling rigs are designed for mineral exploration, studying the mineral resource base and preparing technological maps for the extraction of reserves; as well as for geological work for the design, construction and reconstruction of enterprises.

URB 51

Designed for drilling with a depth of up to 300 meters (core method, carbide or diamond crowns with flushing or blowing) at a well angle of 45–95 degrees, it is mounted on a full-capacity three-axle high-cross-country chassis. They use URB, as the manufacturer specifies, for studying the mineral resource base, mineral exploration and preparing technological maps for mining, as well as for geological work in the design, construction and reconstruction of enterprises. In addition, the installation performs tasks such as ensuring production efficiency and industrial safety, monitoring groundwater, examining drainage water reduction systems, taking water samples to determine the chemical composition and genesis of drainage water, performing calculations of tributaries to mine workings, and also monitoring ice formation zones and groundwater breakthrough into mine workings. In addition to core drilling with flushing, the URB-51 allows continuous drilling with cone bits with flushing (blowing) or an air hammer, shock-rope method with driven drums, chisels and chutes, as well as performing screw drilling and screw drilling under casing protection or drilling using hollow augers, pick drills, paddle bits.

Modular Container Construction

We provide reliable modular anaekrans for a wide range of design requirements. The units can be largely varied depending on customer demands.

Metal Platforms

MINAY Group develops and installs constructions and modules for different sized warehouses, plants and factories, farms, various stadiums, office buildings, shopping and entertainment centres, pedestrian crossings, and other large and small-scale civil and industrial facilities. The metalworking area offers a set of services, ranging from the design and development of the projects and all construction work, starting with the job descriptions, to the delivery of the finished project. Design of metal structures and design of objects are carried out on the basis of a special program, taking into account the regions and its climatic conditions.

Sucker Rod

A steel rod that is used to make up the mechanical assembly between the surface and downhole components of a rod pumping system. Sucker rods are 7 to 9 m long and threaded at each end to enable the downhole components to be run and retrieved easily. They are produced to the API 11B specification. The specification varies to the customers need and this includes anti-corrosion and anti-abrasion resistant coating.

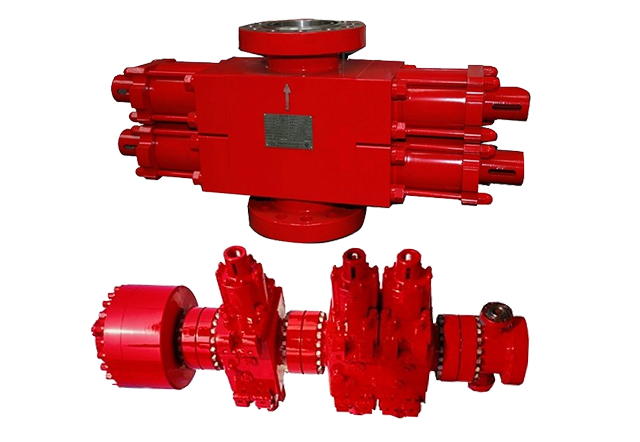

Blowout Preventor

A large valve at the top of a well that may be closed if the drilling crew loses control of formation fluids. The BOP rams are manifold, including: blind ram, pipe ram, shear ram and variable diameter ram. The BOP is made to the API 16A specification.

Specialized Oil Exploration Pipes

The insulated casing uses water-based fibre cloth material with a three grade vacuum pump equipment, automatic welding machine and MT. These guarantees a high degree of vacuum level that meets the insulation grades D and E. These vacuum insulated casing use an effective getter to ensure the tubing insulation grade do not decrease after a long time of outdoor storage. The vacuum insulated casings are reusable. They retain desired insulation properties after being used several times and are made to the API 5CT classification.

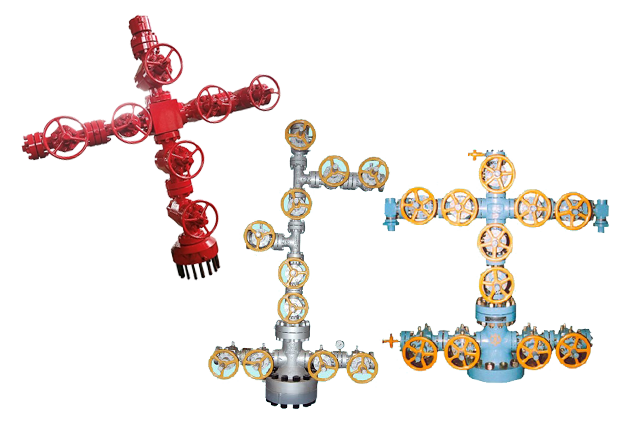

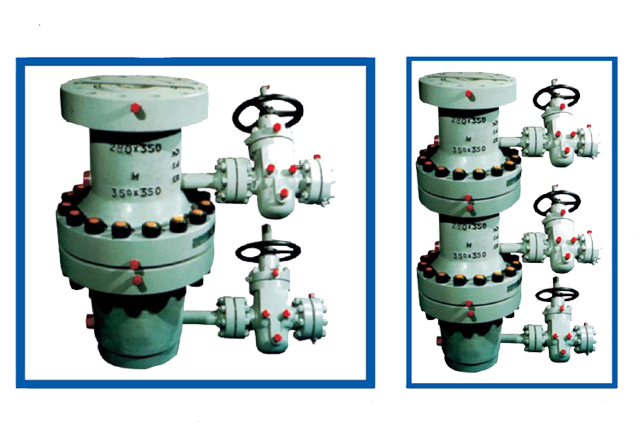

Wellhead and Christmas Tree Assembly

Assembly of valves, spools, pressure gauges and chokes fitted to the wellhead of a completed well to control production. Christmas trees are available in a wide range of sizes and configurations, such as low- or high-pressure capacity and single- or multiple-completion capacity. The conventional wellhead and X-mas tree equipment can be manufactured to the API 6A standard connection or the GOST Standard, which makes it is easy to install, maintain and is interchangeable.

CASING HEAD ОКК1, ОКК2

The casing head OKK are intended for binding of two or more columns and check of pressure in inter-column space. Column bindings are produced at operating pressure of 21 and 35 MPa. Depending on the structure of downhole environment, bindings are produced as the following: Usual - for media containing petroleum, gas, gas-condensate, flush fluid, cement slurry, particles of bored soil, water and their mixtures. Corrosion-resistant (K2 and K2i)- for media containing oil, gas, gas-condensate, flush fluid, cement slurry, particles of bored soil, water and their mixtures containing H2O and C2O up to 6 % in volume.

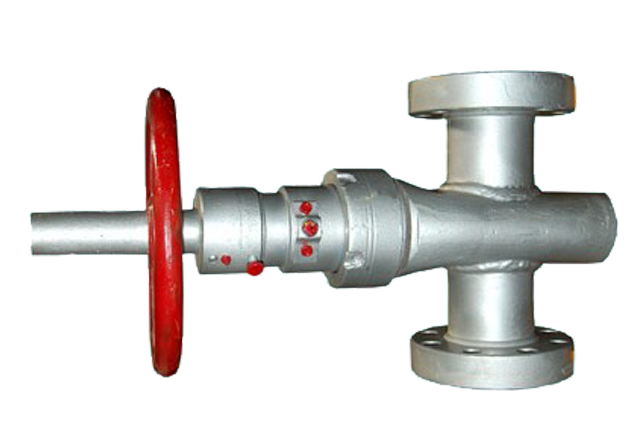

GATE VALVE "3М-65х21"

Gate valve 3M-65X21is intended for capping transitory openings of orifice equipment of wells.

GATE VALVE "3МС1-100х35"

Gate valve 3MC1 -100x35 is intended for capping flow openings of wellheads of well orifices.

Pumping Unit Cementing Units

Designed for hydrochloric acid transportation and injection into wells in acidizing of bottom-hole formation zone. The pumper, mounted on KpA3-257 motor vehicle chassis, includes a high pressure pump, a transmission, a tank, a manifold, an auxiliary pipeline.

Oilfield Packer

We provide two main types of packers for oil and gas, these include tube and external casing packer. They are suitable for applications such as water sealing, pocket cement, gas channeling, anti-edge water, anti-gas cut with excellent effect. Based on the conventional cementing techniques, an external packer can be installed between the isolation layers. This results in a reliable and long-lasting separation between the layers. Due to the varying application requirements in this industry, our packer oil and gas come in different configurations. These include: filling formula everlasting packer, filling compression integrated existence packer, water and oil self-expendable packer, metal cage large hole compression packer etc. This allows for adaptability to high pressure, resistant to high temperature, allows for future system expansion-upgrade and guarantees long service lifespan.